|

|

Post by René on Oct 24, 2021 17:29:40 GMT

An interesting development that has been taking place in the slot car scene for a while now is 3D printing. At first it was mainly chassis and some spare parts but now there is the Italian company TA71 who are producing a large range of cars that are completely 3D printed and the quality is very good. The shape and proportions of the bodies is almost perfect as they are printed from blueprint drawings of the real cars. The body surface does need some smoothing for a good finish but then you have a great car. The chassis are compatible with Policar and Slot.it parts. I ordered two cars recently to have a go myself. Obviously two Ferrari models!  Will keep you posted on the progress.   |

|

|

|

Post by robmarsh on Oct 25, 2021 8:09:17 GMT

Yep I am hoping to get a 1/12 3D print of Carlos Reuteman to go with my Ferrari 312T3

|

|

|

|

Post by René on May 20, 2023 17:11:12 GMT

These are three new additions to projects I'm trying to realize sometime in the near future (even if John Charles once said to me I would never finish them all...). Again 3D printed kits from the Italian manufacturer TA71. I already had a few (see above), but couldn't resist these new releases! The 3D printed bodies are super accurate because they are printed using original blueprint and cad cam drawings. The kit itself is easy to assemble and everything fits perfectly, but the difficulty lies in the finish of the bodywork. Due to the printing process, it is not perfectly smooth and will first have to be sprayed with a filler primer and then sanded smooth. I have yet to start my first so I can't wait to see how this turns out. But the cars look great!

Ferrari 275 GTB. One of Enzo's favorites. For now I have a yellow car in mind.

Ferrari 512 Berlinetta Boxer. One of my dream cars when I was a young boy. I think I will do it in Ferrari red with black on the lower part of the body. Dallara IndyCar DW12, 2022 season. My first modern IndyCar. I might do the Will Power #12 car but that depends a bit on what decals are available. If this turns out nice I will probably buy another one to have a set. Dallara IndyCar DW12, 2022 season. My first modern IndyCar. I might do the Will Power #12 car but that depends a bit on what decals are available. If this turns out nice I will probably buy another one to have a set. And of course a box full of the necessary parts to turn them into running slot cars.   |

|

|

|

Post by robmarsh on May 21, 2023 9:48:03 GMT

Amazing Rene, speak to Michael Porter at Indycals, he may be able to help.

|

|

|

|

Post by René on May 21, 2023 12:26:06 GMT

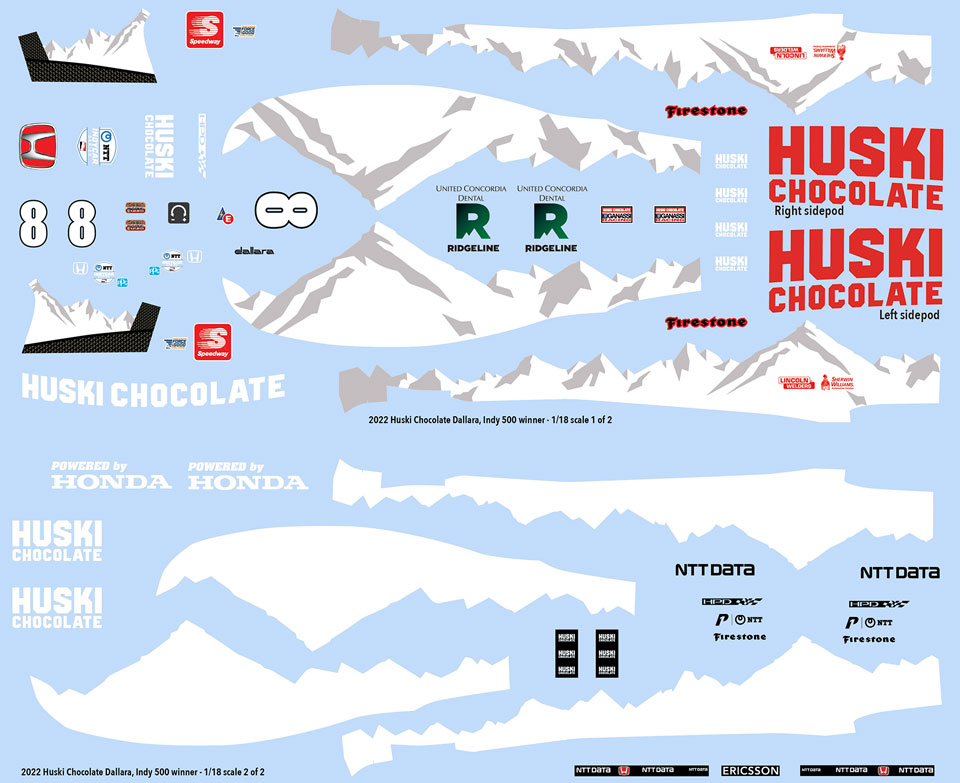

Amazing Rene, speak to Michael Porter at Indycals, he may be able to help. It is amazing Rob. Just look at that front suspension of the Dallara how it is printed in one piece with the chassis. And it is very sturdy, much more than how 'normal' cars are made now. It can even bend without breaking and jump back into shape. This is definitely the future of model/slot cars. I just sprayed a couple of Ferrari bodies with the filler primer for the first time to see how this works out. Yes Michael Porter is a good address for decals, thanks. He has decals for the Will Power car and for the Marcus Ericsson Indy 500 winner. I am sure he will make more 2022 cars but these two are very nice. Will Power 2022 champion, road course livery.  Marcus Ericsson, Indy 500 winner livery Marcus Ericsson, Indy 500 winner livery  |

|

|

|

Post by robmarsh on May 21, 2023 18:41:28 GMT

Actually not only the future of slot cars but of modelling in general. There are some amazing aftermarket sets for aircraft, tanks etc coming out of Eastern Europe.

|

|

|

|

Post by René on May 21, 2023 19:38:34 GMT

Actually not only the future of slot cars but of modelling in general. There are some amazing aftermarket sets for aircraft, tanks etc coming out of Eastern Europe. Yes that's what I meant. In a few years' time, scale models, slot cars and kits will all be 3D printed. You can print anything, no matter how complicated. Rob, do you have any tips on how I can get the bodies as smooth as possible? How would you do that? First layer of primer filler on these four.  |

|

|

|

Post by Carl on May 21, 2023 21:03:49 GMT

First layer of primer filler on these four.  I am once again the student in class distracted by my own thoughts...

I immediately noticed how the bare-body Indycar resembles a raptor in a steep dive. With wings swept back for maximum aerodynamic efficiency, raptors sometimes reach speeds above 200 mph.

|

|

|

|

Post by robmarsh on May 22, 2023 7:14:00 GMT

Actually not only the future of slot cars but of modelling in general. There are some amazing aftermarket sets for aircraft, tanks etc coming out of Eastern Europe. Yes that's what I meant. In a few years' time, scale models, slot cars and kits will all be 3D printed. You can print anything, no matter how complicated. Rob, do you have any tips on how I can get the bodies as smooth as possible? How would you do that? First layer of primer filler on these four.  Hi Rene I am not sure how effective the primer works but the way that I use is to sand it down with ever finer water paper and then to go on to micromesh modelling cloth which I think ends with 12000. It is a lot of work and getting into some areas is difficult. A very fine cloth or soft wool on a drill might rest the fingers and hand. You have to be careful not to destroy the detail. Hope this helps. |

|

|

|

Post by René on May 22, 2023 8:51:28 GMT

First layer of primer filler on these four. I am once again the student in class distracted by my own thoughts...

I immediately noticed how the bare-body Indycar resembles a raptor in a steep dive. With wings swept back for maximum aerodynamic efficiency, raptors sometimes reach speeds above 200 mph. Nature is always ahead of us. We think that we come up with something beautiful or clever, but then it already exists in nature! |

|

|

|

Post by René on May 22, 2023 8:59:13 GMT

Yes that's what I meant. In a few years' time, scale models, slot cars and kits will all be 3D printed. You can print anything, no matter how complicated. Rob, do you have any tips on how I can get the bodies as smooth as possible? How would you do that? First layer of primer filler on these four. Hi Rene I am not sure how effective the primer works but the way that I use is to sand it down with ever finer water paper and then to go on to micromesh modelling cloth which I think ends with 12000. It is a lot of work and getting into some areas is difficult. A very fine cloth or soft wool on a drill might rest the fingers and hand. You have to be careful not to destroy the detail. Hope this helps. Thanks Rob, this helps for sure! I decided to use the filler primer after reading about it on a 3D print forum and it looks like it does the trick. Yesterday evening I did a little test by carefully sanding the roof of the 512BB with a very fine sandpaper and it turned quite smooth I must say. The challenge is indeed the hard to reach areas while saving the detail. It doesn't have to be as perfect as your model cars, it's a slot car after all but a smooth finish would be nice. |

|

|

|

Post by mikael on May 29, 2023 14:33:08 GMT

Very interesting :-) Yes, "Additive Manufacturing", where the necessary material is added - contrary to traditional machining, where the unnecessary material is removed - has become a hot topic across virtually all manufacturing industries. For sure, from an energy perspective, it does seem the right way to go.

|

|

|

|

Post by Carl on May 29, 2023 14:54:26 GMT

Quoted from General Electric's website:

"It is yet, another technological advancement made possible by the transition from analog to digital processes. In recent decades, communications, imaging, architecture and engineering have all undergone their own digital revolutions. Now, AM can bring digital flexibility and efficiency to manufacturing operations.

Additive manufacturing uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. As its name implies, additive manufacturing adds material to create an object. By contrast, when you create an object by traditional means, it is often necessary to remove material through milling, machining, carving, shaping or other means.

Although the terms "3D printing" and "rapid prototyping" are casually used to discuss additive manufacturing, each process is actually a subset of additive manufacturing.

While additive manufacturing seems new to many, it has actually been around for several decades. In the right applications, additive manufacturing delivers a perfect trifecta of improved performance, complex geometries and simplified fabrication. As a result, opportunities abound for those who actively embrace additive manufacturing."

Truly amazing, but I can't help wondering what the great classical artists would think of computer aided design.

|

|

|

|

Post by René on May 29, 2023 17:14:40 GMT

These are very interesting developments. Of course my slot car bodies are just hobby projects, but indeed also in the grown-up world  this technique is taking an increasing important place. I know from clients of my business who are active in engineering that they do a lot of research into this. |

|